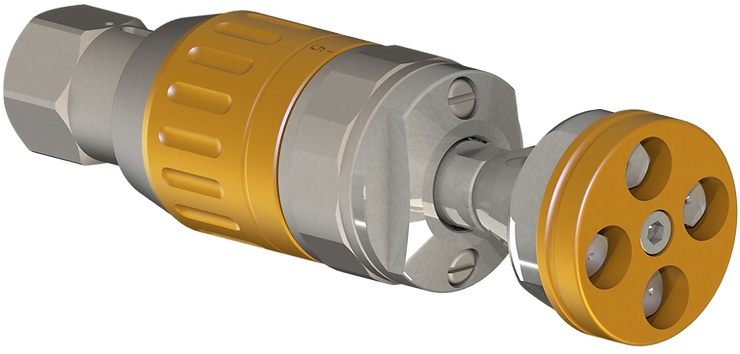

Lemasa announces the launch of the Scimitar H Nozzle, which combines high durability, easy maintenance, and operation for surface treatment in manual or automated operations.

The Scimitar H Nozzle ensures efficiency, high performance, and safety during the Hydrojetting process, thanks to its new rotation control technology by a centrifugal system, delivering excellent results for the treatment of metal surfaces, ship hulls, and/or oil platforms, as well as coke or rubber removal.

The Scimitar H Nozzle is a product developed with high-quality materials and advanced technology. Its efficiency has been proven by industry professionals, who have demonstrated a significant reduction in MTTR (Mean Time To Repair) and an increase in MTBF (Mean Time Between Failures). As a result, this nozzle provides a considerable increase in productivity for cleaning and surface treatment processes, ensuring effective and long-lasting results for customers.

Technical Specifications:

| Working Pressure |

(22K) – 850 bar – 1500 bar (22,000 psi) (40K) – 2000 bar – 2800 bar (40,000 psi)

| Nozzle Holder |

For both the 22K and 40K versions, all nozzle configurations use only 2 types of nozzle holders (15° and 17°).

| Rotation | –

Automatic rotation control (22K) – 1000 to 1800 rpm (40K) – 1700 to 2400 rpm