Increase the Power of Your Hydroblasting With Our High-Performance Acessories

Pumps, Acessories, Nozzle and Specieal devices. Click the button below and see our products.

Sugar and Ethanol, Naval Industry, Petrochemical, Civil Construction, Mining and Cement Industry

OVER 30 YEARS PROVIDING SOLUTIONS FOR HIGH PRESSURE CLEANING

OUR PRODUCTS

Industry sectors

Sugar and Ethanol

Internal cleaning of: Pre-evaporators, Evaporators, Heaters, Boilers and Syrup Line

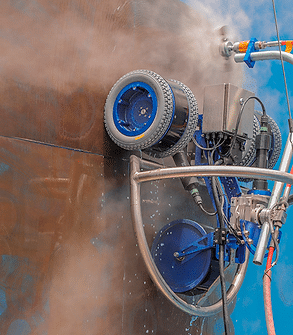

Naval Industry

Surface preparation, Epoxy paint removal, Pipeline cleaning, Boiler cleaning and Barnacle removal

Petrochemical Industry

Heat exchanger cleaning, Pipeline cleaning, Refractory cutting, Tank surface repair and Boiler cleaning and cold plate cutting

Civil Construction

Hydrodemolition, Concrete Apicoamento, Surface preparation, Concrete cleaning and Cleaning forms and shoring

Mining

Mineral cutting, General maintenance, Pipe cleaning , Cleaning of the Magnetic and Separator Matrix

Cement Industry

Pipeline cleaning, Refractory cutting and Cyclone tower cleaning

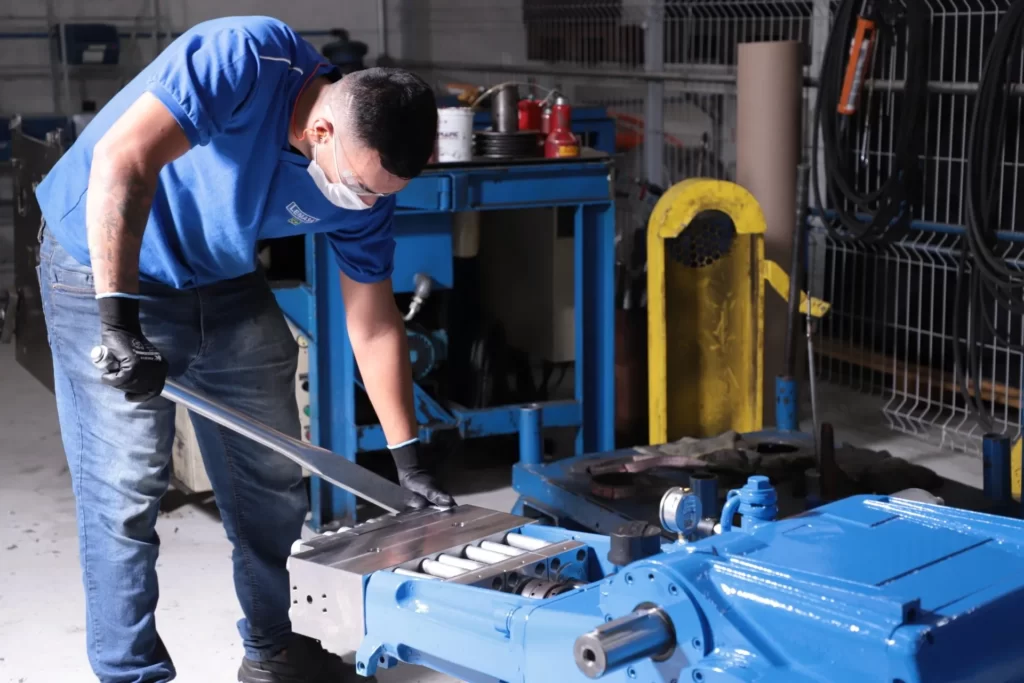

LEARN MORE ABOUT LEMASA

With vast experience and excellence in the industry, Lemasa specializes in hydrojetting solutions for different sectors. Our company offers a wide range of high-pressure solutions designed to meet the diverse needs of the industry.

We constantly invest in technology, resulting in innovative and efficient solutions for different industrial sectors. Our hydrojet pumps and accessories are intelligently designed, providing precise and high-performance applications.

Standing out for our in-house manufacturing, we have a large factory structure of over 17,000 square meters. This allows us to produce quality equipment, ensuring full control over the manufacturing process and guaranteeing product reliability.